- ZHUHAI JIALI HARDWARE CO.,LTD.

- +86-756-8586520

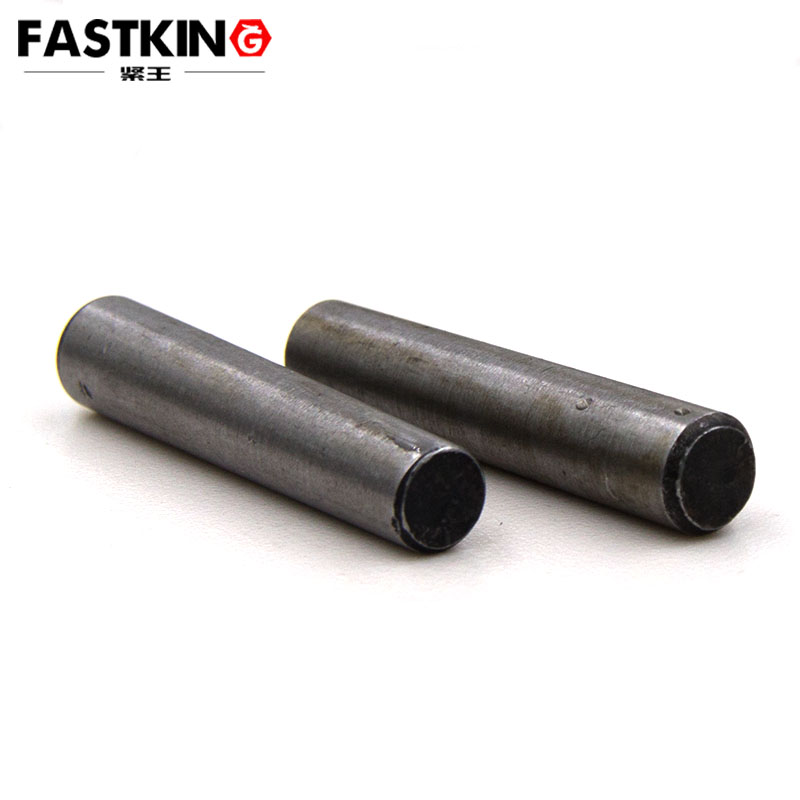

Cylindrical pin gb119

- Product description:There are also common cylindrical pin, internal thread cylindrical pin, thread cylindrical pin, pin with hole, elastic cylindrical pin and so on.

It is mainly used for positioning and can also be used for connection. It is fixed in the pin hole by means of interference fit. When cylindrical pins are used for positioning, they usually bear no load or only a small load. The number of pins used is not less than two, and they are arranged symmetrically in the overall structure of the connected parts, with the distance between them as large as possible. The length of the pin in each connected part is approximately 1 to 2 times its small diameter.

The ordinary cylindrical pin is the most basic type under the GB119 standard, with a "solid cylindrical" structure as its core. It achieves precise positioning by virtue of its high-precision outer diameter. Its diameter tolerance strictly complies with the provisions of GB119, with common tolerance grades of h8 and h9. It forms a transition fit or interference fit with the H7 and H8 tolerances of the part's pin hole — the transition fit is suitable for positioning scenarios requiring frequent disassembly, such as the positioning of guide pillars in molds, which can ensure positioning accuracy while facilitating mold maintenance; the interference fit is applicable to structures requiring long-term fixation, such as the connection between gears and shafts in mechanical equipment. Through interference assembly, no gap is ensured, avoiding abnormal noise or wear caused by positioning deviation during gear operation. Ordinary cylindrical pins are mostly made of 45# steel or stainless steel. After quenching and tempering, their hardness can reach HRC28-32, featuring good shear resistance and the ability to bear lateral loads between components. They are widely used for basic positioning in machine tools, automotive parts, instruments and meters and other fields.

The internally threaded cylindrical pin is developed on the basis of the ordinary cylindrical pin, with internal threaded holes processed at one or both ends, solving the problem of difficult disassembly of ordinary cylindrical pins. When the cylindrical pin and the pin hole are in interference fit, ordinary pins need to be taken out by tapping with a hammer, which is easy to damage the pin hole or the pin body. However, the internally threaded cylindrical pin can have a bolt screwed into it through the internal thread, and the pin body is pulled out of the pin hole by the tensile force of the bolt. It is especially suitable for the disassembly of pins in deep holes or closed spaces — for example, the positioning pin of an engine cylinder block is installed in a deep hole inside the cylinder block, which is difficult to take out by ordinary methods. The internal thread design allows easy disassembly with a special puller tool, reducing the risk of cylinder block damage. In addition, the internal thread can also be used for auxiliary installation. In some scenarios, a positioning bolt can be screwed in through the thread to ensure the coaxiality of the pin body and the pin hole, improving assembly accuracy. It is suitable for aerospace, high-end equipment and other fields with high requirements for disassembly convenience and accuracy.

The threaded cylindrical pin integrates external threads on the surface of the cylindrical pin, featuring both positioning and connection functions. One end of it is a cylindrical positioning section, and the other end is processed with external threads (such as M6, M8). The positioning section controls the tolerance in accordance with the GB119 standard to ensure positioning accuracy; the threaded section can be matched with nuts or internal threaded holes of parts to realize the fixed connection of components — for example, as a connector for furniture, the positioning section of the threaded cylindrical pin is inserted into the pin hole of the furniture board, and the threaded section is tightened with a nut, which not only ensures the positioning alignment between the boards but also provides sufficient connection strength to prevent furniture loosening. Compared with ordinary bolts, the positioning section of the threaded cylindrical pin can limit the radial displacement of components, making it more suitable for scenarios requiring both positioning and connection, such as the splicing of medical device housings and the assembly of small equipment frames.

The slotted pin realizes the dual functions of "positioning + auxiliary fixation" by processing transverse holes in the middle or at the end of the cylindrical pin. Opening pins, steel wires or pin shafts can be inserted into the transverse holes to prevent the cylindrical pin from falling off in a vibrating environment — for example, in the positioning of connecting rods of agricultural machinery, high-frequency vibration during mechanical operation easily causes the loosening of ordinary cylindrical pins. The slotted pin is locked by inserting an opening pin, ensuring the stable connection between the connecting rod and the crankshaft and avoiding safety accidents. The hole position size and hole diameter of the slotted pin must comply with the supporting requirements of GB119 to ensure accurate adaptation to locking parts such as opening pins. It is commonly used in outdoor operation machinery such as tractors and harvesters, as well as in the positioning of the suspension system of automobile chassis.

The elastic cylindrical pin is the only type with elastic deformation capacity. It is made of metal strips by rolling, presenting a hollow cylindrical shape with axial notches on the surface, and realizing adaptive assembly through elastic deformation. Different from solid cylindrical pins, the elastic cylindrical pin generates radial elastic force due to extrusion during installation, fitting closely with the pin hole. Even if there is a small dimensional deviation in the pin hole, it can ensure positioning accuracy through elastic compensation; at the same time, the elastic structure can absorb vibration energy and reduce the impact between components, making it suitable for scenarios with frequent vibrations, such as the positioning of synchronizers in automobile gearboxes and the fixation of motor end covers. In addition, the installation of elastic cylindrical pins does not require strict control of interference, and has lower requirements on the processing accuracy of pin holes, which can reduce the manufacturing cost of parts. It is widely used in mass production fields such as household appliances, power tools and automotive parts.

In selection and application, comprehensive judgment should be made based on the GB119 standard and actual needs: for basic positioning without frequent disassembly requirements, ordinary cylindrical pins are preferred; for convenient disassembly in deep holes or closed spaces, internally threaded cylindrical pins are selected; for scenarios requiring both positioning and connection, threaded cylindrical pins are suitable; for vibration environments requiring anti-falling, slotted pins are chosen; for scenarios with limited pin hole accuracy and frequent vibrations, elastic cylindrical pins are the better option. In terms of material selection, stainless steel is preferred for humid environments, and 45# steel treated by quenching and tempering is used for scenarios bearing large loads, ensuring compliance with the performance requirements of GB119.

Zhuhai Jiali Hardware Products Co., Ltd., founded in 2008, is an enterprise specializing in the production and sales of industrial fastener products. Currently, the company's main products include hexagon head screws, hexagon socket screws, micro screws, set screws, various types of nuts, threaded rods, flat washers, spring washers, open retaining rings, various pattern washers, 12.9-grade alloy steel high-strength screws, hexagon socket wrenches and box-end wrenches. It can also customize non-standard products according to drawings. The products mainly comply with national standards (GB), German standards (DIN), American standards (ANSI), British standards (BS) and international standards. The main industries served include automobile, electronics, medical equipment, hardware, machinery, shipbuilding, chemical industry, communications, construction and so on. At the same time, all kinds of materials are available. Welcome to contact us.