The material selection for shaft parts revolves around two core principles: "performance adaptation" and "economic rationality", with comprehensive consideration of strength, stiffness, wear resistance, and manufacturing processability. Strength is the fundamental requirement for shaft parts. Based on the type of load (such as tension, bending, torsion) and the magnitude borne by the shaft, materials capable of withstanding the corresponding stress should be selected to avoid fracture or plastic deformation during use. Stiffness is related to the deformation of the shaft under load; excessive deformation will lead to a decrease in transmission accuracy. Especially in scenarios such as precision machine tool spindles and automobile gearbox shafts, insufficient stiffness will directly affect the operational stability of the equipment. Wear resistance targets the contact areas between the shaft and components such as bearings and gears; frequent friction is prone to surface wear, so wear-resistant materials should be selected or surface treatments should be applied to improve wear resistance. Manufacturing processability affects production efficiency and costs; materials need to be easy to cut, forge, and heat-treat to avoid a sharp increase in manufacturing costs due to complex processes. For example, if an ordinary transmission shaft bears a small load, easily processable carbon steel can meet the requirements; however, the main shaft of an aero-engine bears high temperatures and high loads, so high-strength alloy steel must be used, and its performance should be improved through complex heat treatment processes. Although the cost is higher, it can ensure reliability under extreme working conditions.

The commonly used materials for shaft parts are mainly carbon steel and alloy steel, each with distinct focuses in terms of performance and application scenarios. Carbon steel has become the first choice for ordinary shaft parts due to its advantages of low cost and good processability, among which Q235 and 45# steel are the most widely used. Q235 steel is low-carbon steel with low strength but good plasticity, suitable for manufacturing shafts that bear small loads and have low precision requirements, such as auxiliary shafts of light transport aircraft. 45# steel is medium-carbon steel; after quenching and tempering treatment (quenching + high-temperature tempering), it achieves a balanced combination of strength and toughness, with a hardness of up to HRC22-28. It can meet the needs of most general mechanical shafts, such as centrifugal pump shafts and reducer transmission shafts. Moreover, 45# steel has excellent machinability and can be quickly processed into shape through turning, milling, and other processes, significantly reducing production costs. Alloy steel, on the other hand, is made by adding alloying elements such as chromium, nickel, and molybdenum to carbon steel, which significantly improves its strength, toughness, and wear resistance. It is suitable for harsh working conditions such as high loads, high temperatures, and corrosion. For instance, 40Cr alloy steel (containing chromium) has a strength more than 30% higher than that of 45# steel after quenching and tempering, making it suitable for manufacturing shafts that bear large impact loads, such as automobile half-shafts and machine tool spindles; 1Cr18Ni9Ti stainless steel (containing chromium, nickel, and titanium) has excellent corrosion resistance and can be used as a corrosion-resistant shaft in chemical equipment, which is not prone to rusting when used in acid-base solution environments for a long time.

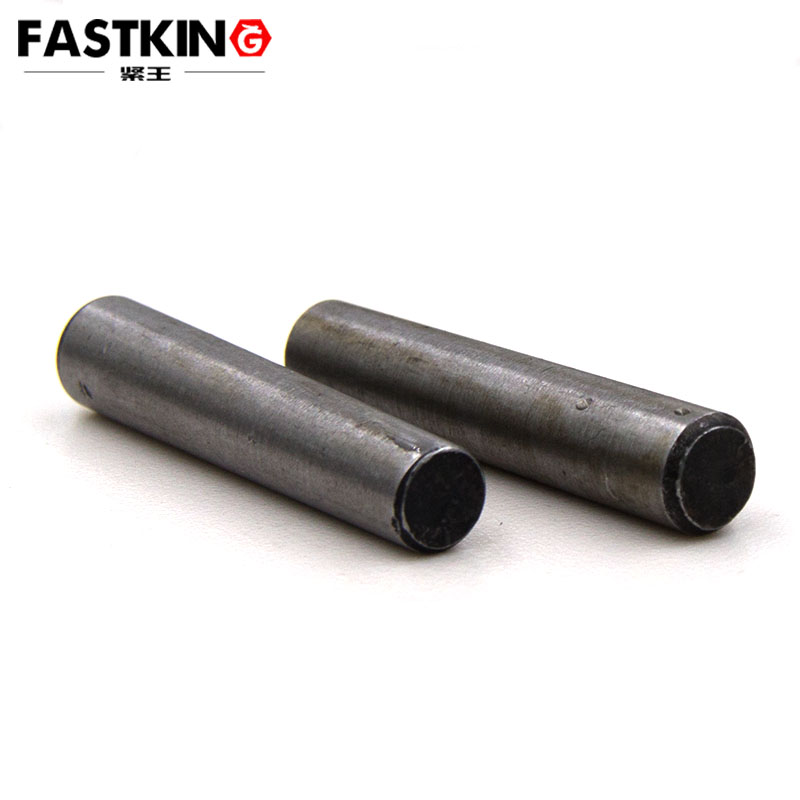

As a type of standardized fastener, the pin shaft differs in function from shaft parts. It is mainly used at the hinge joint of two parts to form a hinged connection, which can not only realize static fixed connection but also allow relative movement between the connected parts. The core advantages of the pin shaft lie in "standardization" and "reliability". Its international standard is ISO 2341:1986, and the domestic standard is GB/T882-2008. These standards clearly specify the dimensional tolerances, material requirements, surface treatments, and other parameters of the pin shaft, ensuring the interchangeability of pin shafts produced by different manufacturers and reducing procurement and maintenance costs. The pin shaft is usually locked with a cotter pin. During installation, the cotter pin is inserted into the hole at the end of the pin shaft, and then both ends of the cotter pin are bent apart to prevent the pin shaft from falling off under vibration or impact. This locking method has a simple structure, reliable operation, and is easy to disassemble (only by cutting the cotter pin). It is widely used in various hinged structures, such as the link hinge of the tractor suspension system and the bucket hinge of construction machinery.

The pin shaft has an extremely wide range of applications, covering key equipment in multiple industries. In the field of environmental protection equipment, pin shafts are used for the hinge connection of grid machines in sewage treatment equipment; due to the need to withstand humid environments, stainless steel is usually selected as the material. In medical equipment, the folding joints of wheelchairs and the adjustment mechanisms of operating tables rely on pin shafts to achieve flexible rotation; the pin shafts are required to have a smooth surface and high precision to avoid scratching patients or affecting the adjustment accuracy of the equipment. For the hinge connection of signal tower brackets in communication equipment and the connection of transmission line hardware in power facilities, the pin shafts need to be exposed outdoors for a long time and thus require weather resistance; carbon steel treated with hot-dip galvanizing or stainless steel is mostly used. In food machinery, since pin shafts are in direct contact with food, they must be made of 304 stainless steel that meets food safety standards, and their surfaces need to be polished to prevent bacterial growth. In the fields of petrochemical engineering and ship assembly, pin shafts need to withstand corrosion from seawater and oil stains, so corrosion-resistant alloy steel is often used. The connection of building curtain walls, the flange hinge of pump and valve pipelines, and the connection of components in amusement facilities in open-air occasions also all rely on pin shafts to achieve stable hinge functions.

From the precise material selection of shaft parts to the standardized application of pin shafts, both reflect the principle of "performance adaptation and economic rationality" in mechanical design. The differentiated application of carbon steel and alloy steel meets the performance requirements of shaft parts under different working conditions; while the standardized pin shaft, with its reliable hinge and locking functions, has become a core component for hinged connections in various industries. Together, they provide support for the stable operation of mechanical equipment.

Zhuhai Jiali Hardware Products Co., Ltd., established in 2008, is an enterprise specializing in the production and sales of industrial fasteners. At present, the main products of the company are hexagon screw, hexagon screw, micro screw, set screw, various kinds of nuts, teeth, flat pad, spring pad, split ring, various kinds of colorful washer, 12.9 grade alloy steel high strength screw, hexagon wrench, etc Box spanner can also be customized according to the drawing. Products mainly comply with the national standard, German standard, American Standard, British standard and international standard. The main service industries are automobile, electronics, medical equipment, hardware, machinery, shipping, chemical industry, communication, construction, etc. at the same time, all kinds of information should be complete, welcome to contact us.